American Made, Iron Clad Protected - Discover the Industries Best Warranty.

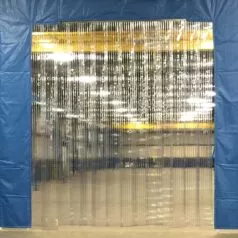

Insulated Curtain Wall

Insulated Curtain Wall – Stationary, Flexible Space Separation to Create Your Own Storage Rooms

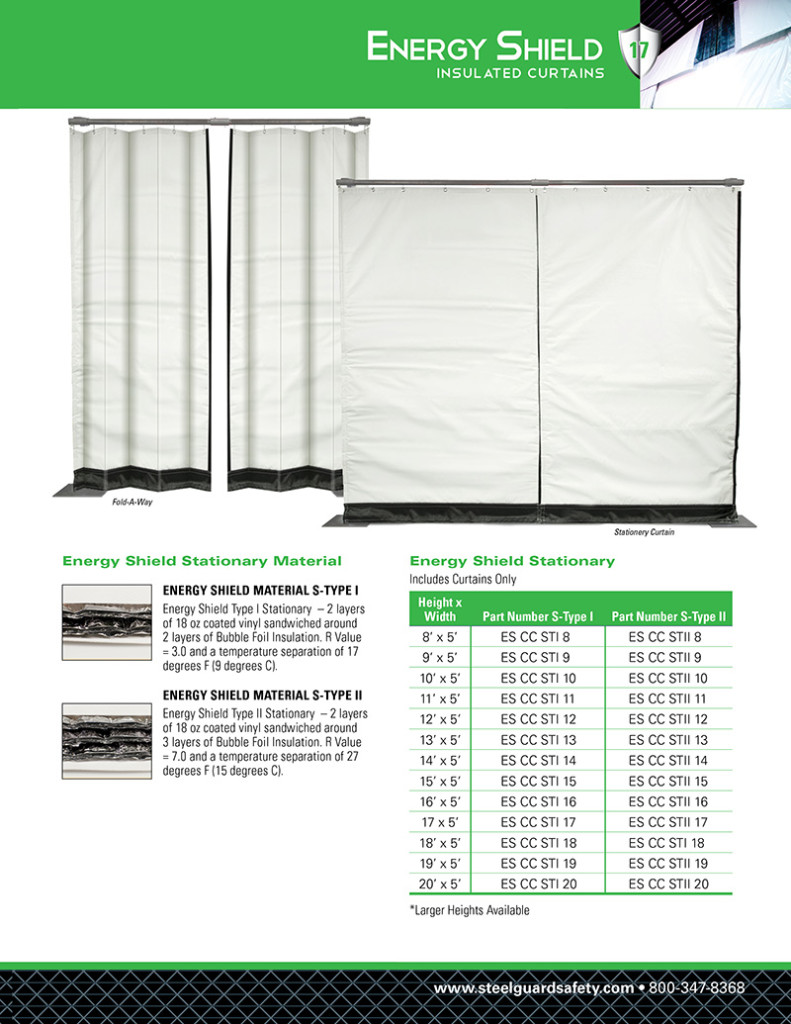

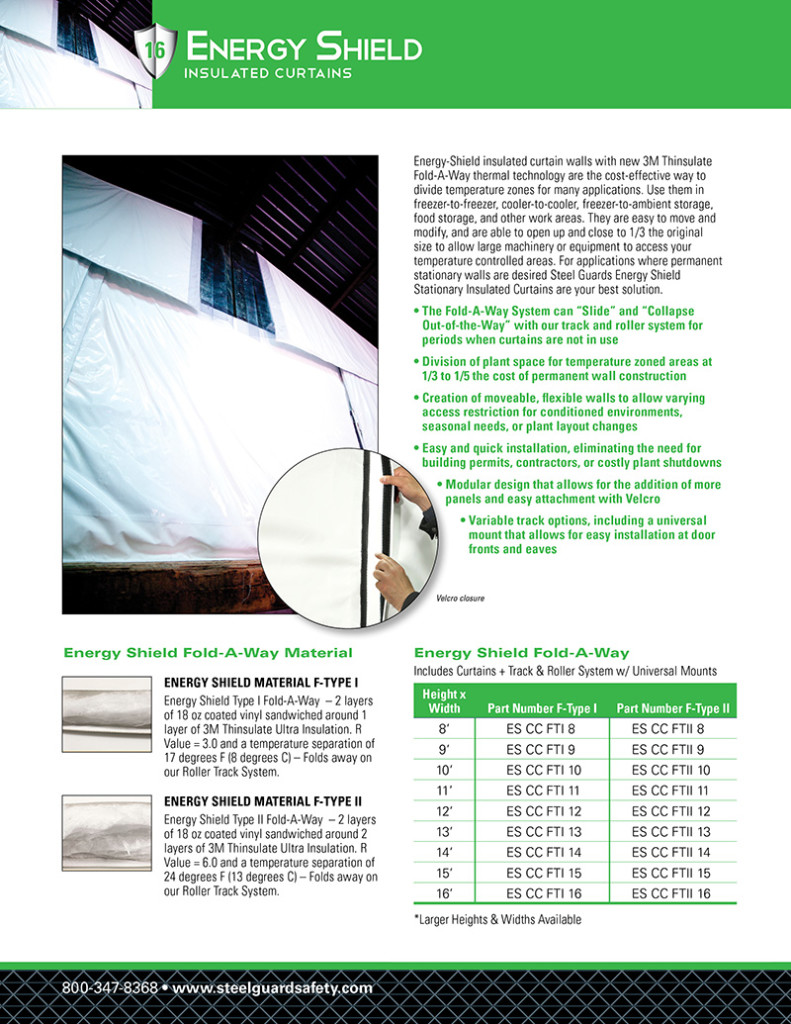

Energy-Shield insulated curtain walls are a cost-effective way to divide temperature zones for freezer-to-freezer, cooler-to-cooler, and freezer-to-ambient storage and work areas. Flexible to move and modify if your Cold Storage Warehouse or Manufacturing needs change. The Insulating Curtain Panels are available in multiple R Values, ranging from R-3 to R-20 depending on substrate. The Insulated Curtain Walls can hang from trusses, and have many options including strip curtains, floor mount straps, and floor sweeps.

Industrial Insulated Curtain Wall Benefits

- Allows you to Design & Re-Design Temperature Zoned Spaces

- The Panels are 5′ Wide and Attach Modularly for Any Size.

- Energy Shield Curtains do Not Need Building Permits for Installation

- Ideal for Separating Leased Tenants Inside Warehouses

- Controls Humidity in Food Storage and Production Areas.

- Creates Separate Temperature Zones for Products or Employees.

Repurpose and Reuse the Industrial Insulated Curtains

These insulated curtain walls keep rooms effectively in temperature zones. This can make warehouses space more efficient and the ability to make modular freezer and refrigeration zones for cold storage. The panels are also modular so when a warehouse job is complete they can be put away or reconfigured for a new job. According to the EPA Having a Thermal Insulation System like Industrial Insulated Curtains in the Food Industry reduces energy and costs.

Industrial Insulated Curtains Also Prevent Contamination

Industrial Insulated Curtain Walls also keep a constant temperature to prevent overheating and needless energy loss. They also block areas off from dust, chemicals, and other possible contaminants. With the installation of insulated curtain walls in place, your facility will ultimately be cleaner and easier to maintain and provide a considerably safer environment for employees and visitors who may require additional protective measures. If you are needing a foldable solution, check out our Foldable Insulated Warehouse Curtains

Additional Information:

Insulated Curtainwall Common Applications

• Refrigerated & freezer areas

• Warehouse separation with temperature controlled space

• Loading dock areas

• Containment for storage and work space

• Food & beverage industry including food processing lines

• 3 PLS (Third Party Logistics)

• Data centers

• Airports

• Garage dividers/separation & insulation

Our sales staff is available Monday through Friday to answer all of your questions about designing Energy Shield insulated curtainwall. Call 1-800-347-8368 to speak with someone today, or use our Request a quote system and a sales professional will contact you within 24 hours.

Energy Shield Insulated Curtains

Energy Shield Insulated Material

Energy Shield Materials – 2 layers of 18 oz coated vinyl sandwiched around 1, 2, or 4 Layers of 3M Thinsulate Ultra. R Values Range from R-3, R-6, and R-9. All Materials meet NFPA-701 and ATM E-84 guidelines for Flame Retardancy in Buildings. See Materials Tab for More Details.

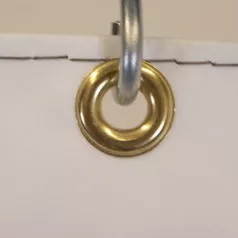

#2 Brass Grommets

#2 Brass Toothed Grommets are spaced every 12″ on center. The curtains can be affixed directly to rafters, or use a Universal L-Channel to affix Panels.

Velcro Side Attachments

2 inch Velcro side attachments are on both sides of the curtain panel to easily seal and attach both sides to multiple curtains to create an infinite length wall.

Floor Sweeps (Add-On)

Velcro attaches to the full length of one run of curtains – Seals bottom of insulated curtain to the floor.

Strip Door Walk/Drive Through (Add-On)

A Vinyl Strip Door can be added for access of Workers or Forklift Traffic between rooms.

Floor Mounts (Add-On)

Floor Mount D-Rings – Included with strap and buckle. Fastens the curtain system to floor.

Part# CA 101

Angle Iron

Energy Shield FT I

2-Layers of 18 oz Coated Vinyl Sandwiched around 1 Layer of Thinsulate 3M Ultra. Meets ASTM E-84 and NFPA-701 Certifications.

Provides Temperature separation of 17 degrees F (9 degrees C). < See Materials Here >

Energy Shield FT II

2-Layers of 18 oz Coated Vinyl Sandwiched around 2 Layer of Thinsulate 3M Ultra. Meets ASTM E-84 and NFPA-701 Certifications.

Provides up to 24°F (13° C) of temperature separation; R-Value of 6.0. < See Materials Here >