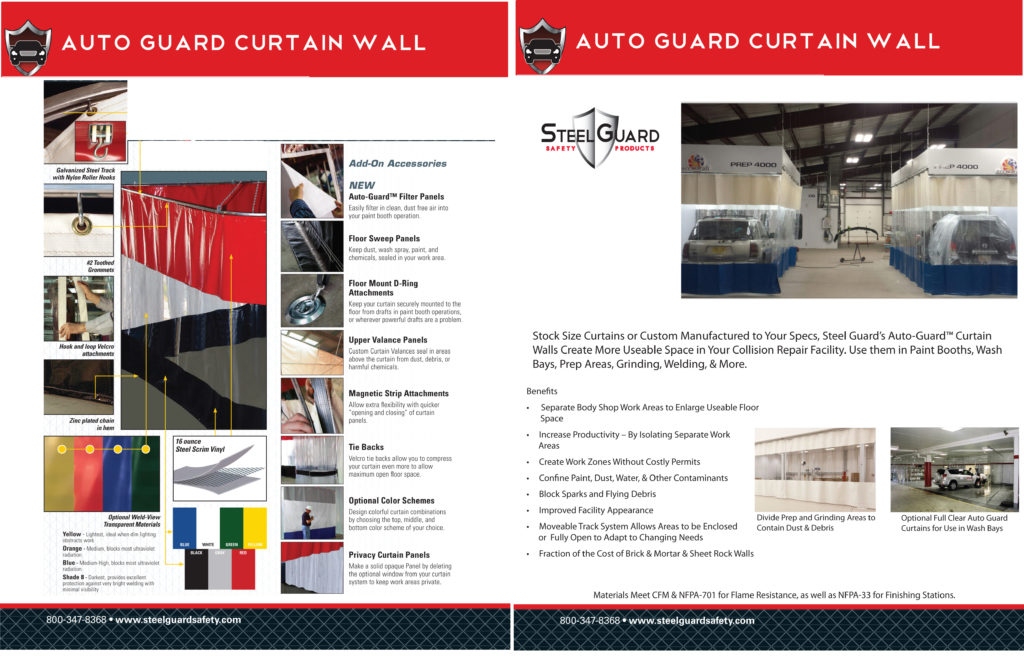

American Made, Iron Clad Protected - Discover the Industries Best Warranty.

Wash Bay Curtains | Car Wash Curtains

Wash Bay Curtains Keep Your Shop Clean – Isolating Spray, Dirt, & Chemicals From Other Work Zones

Wash Bay Curtains provide an enclosed cell to clean Cars, Trucks, and Industrial Equipment. The Curtain Systems can easily retract out of the way with Roller Track Systems when not in use. The Wash Down Curtains are available in Stock or Custom Wash Bay Curtains to create 1, 2, 3 or Multi-Sided Cells. These Wash Bay Curtain Cells can be part of a Wash Bay System to Properly Prep and Dispose of Waste Water. If you are looking for Food Processing Wash Down Curtains see our USDA Grade Wash Down Curtains

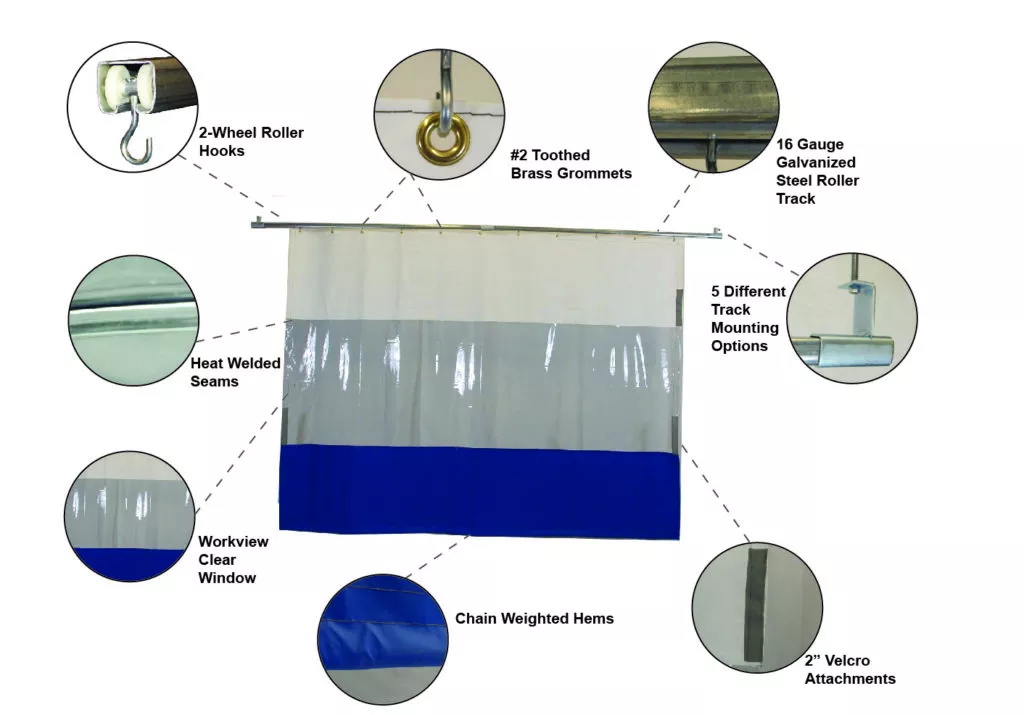

Stock Wash Bay Curtains

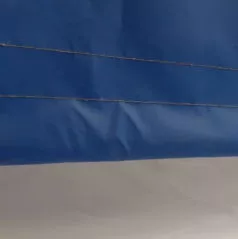

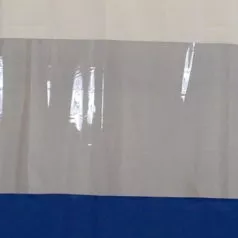

- Color: White Top – Clear Middle – Blue Bottom

- Materials: Top & Bottom – 18 oz Coated Vinyl — Middle – 20 Mil Clear PVC – All Materials Meet NFPA-701 Flame Retardant Standards

- Kit Includes: Wash Bay Curtains w/ Vision Panel, Grommets on Top, Chain Weight in Bottom, Velcro on Sides — Galv. Steel Track, 2-Wheel Nylon Roller Hooks, Universal Splice & Mount Connectors (Works in place of Threaded Rod, Beam to Chain & Wall Mounts), End Stops

- Panels: Connect Multiple Modularly

Ships In: 2 -3 Business Days

Additional Information:

Iron Clad Warranty

6 Year Warranty on Construction and the Peace of Mind of Covering Any Related OSHA Fines. Learn More

Rush Manufacturing

Get your Custom Auto Body Curtain Wall Made in as little as 5 Days (Depends on Order Size)

Low Price Guarantee

We’ll Guarantee the Lowest Price, and if you find a better on we will beat it by 5%

Steel Guard Safety offers custom Wash Bay Curtains designs based on your facility’s needs. To discuss your project with us, you can request a quote online or call 1-800-347-8368 to speak with a representative.

Wash Bay Curtains

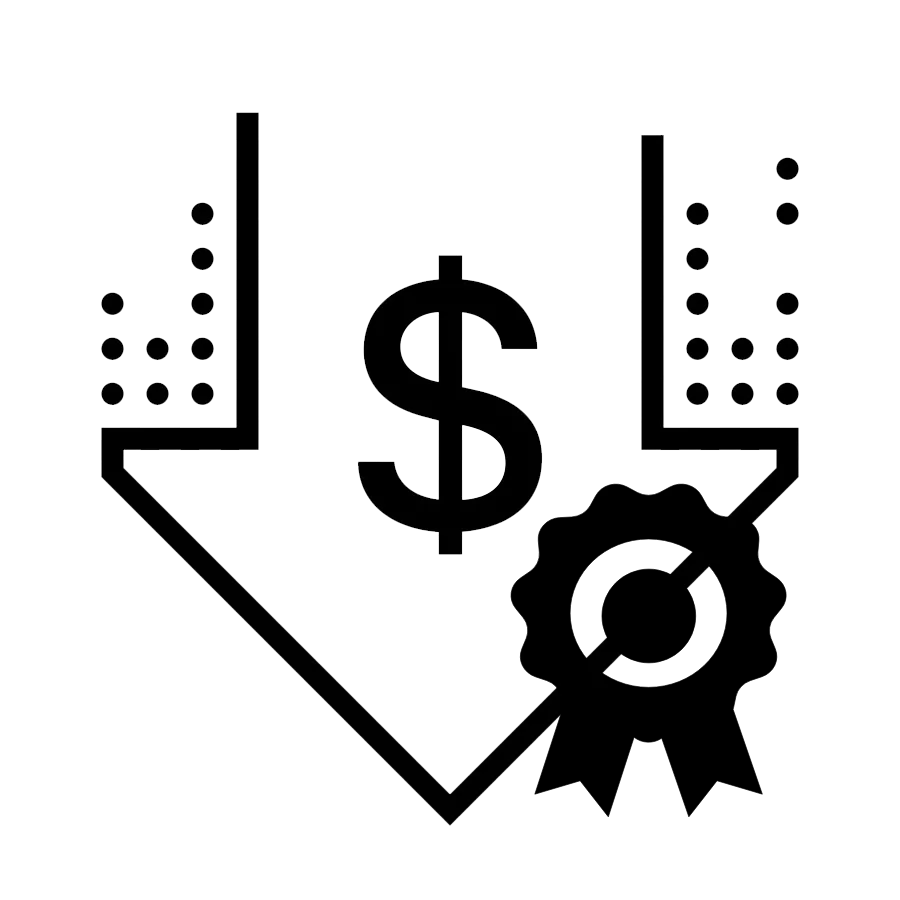

Standard Features & Options

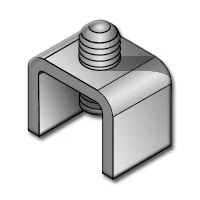

2-Wheel Nylon Roller Hooks

Make for easy sliding and folding of the wash bay curtains. 2-wheel steel roller hooks are available for taller curtain systems.

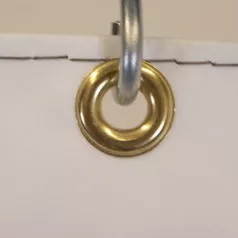

#2 Toothed Brass Grommets

#2 Brass Toothed Grommets are spaced every 12″ on center of the curtains to hang securely on the roller hooks.

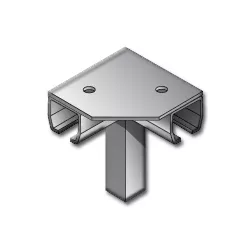

Galvanized Steel Roller Track

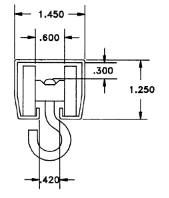

Heavy-Duty 16 gage roller track system which modularly connects track lengths to your desired shape or length. (Dim – O.D. – H-1.25″ x W-1.44″)

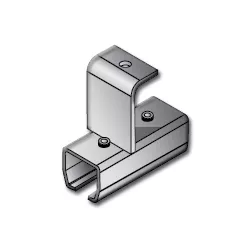

Track Mounting Hardware

5 Different Mounting Options Available Including Universal Mount to use in place for Beam to Chain, Threaded Rod, and Wall Mounts.

Velcro Attachments

2″ Velcro side attachments easily seal and attach both sides of curtains to multiple curtains. Available in standard 2 x 1′ swatches, full length, or custom.

Chain Weighted Hem

Heavy-Duty 3/8 inch Thick Galvanized Chain inserted into the bottom pocket to stabilize the curtain against drafts.

Work-View Clear Window

20 Mil PVC Window – Flame Retardant & double polished for a clear view of workers and operations. Meets CFM, & NFPA-701 standards. (Optional)

Heat Welded Interior Seams

Interior Seams are electronically welded with RF Bar Sealers for an extra tough resistance to tears. Outer Hems are sewn with a heavy-duty double-lock stitched nylon thread.

Floor Sweeps (Add-On)

Vinyl Floor Sweep – Sew-in or Velcro Option – Seals bottom 1 inch gap to seal off dust, dirt, & contaminants.

Part# CA 300 – Sew On Part# CA 299 – Velcro

Floor Mount D-Rings (Add-On)

Floor Mount D-Rings – Included with strap and buckle. Fastens the curtain system to floor against wind & updrafts

Part# CA 101

Adhesive Velcro (Add-On)

2 inch Adhesive Velcro – Attaches any curtain to a brick, metal, concrete, or wood wall or door openings.

Part# CA 677 – 2″ PSA Loop Part# CA 694 – 2″ PSA Hook

Valance Panels (Add-On)

Upper Stationary Curtain Panels – Custom made to Ceiling Design -Ideal when the top half of an area does not need to be opened and contaminants need to be sealed off.

Part# CA 655

Strip Curtain Walk Through (Add-On)

Equip your curtain with the flexibility to walk or drive through without opening your entire system. Can be equipped for man or Forklift Traffic

Part# CA 900

Magnet Attachments (Add-On)

2″ Magnets Attachments provide a quick and easy attaching and un-attaching of multiple curtains.

Part # CA 550 – Sew On<br>Part # CA 551 – Adhesive PSA

18 oz Coated Vinyl FR - Opaque

18 oz per sq/yd Coated Vinyl provides excellent Tear and Tensile Strength while also giving Superior Abrasion Resistance Compared to Laminate Vinyls. Meets Flame Resistant Standards, CFM, NFPA-701 & ASTM E-84.Generally used on the top & bottom panels but can also be selected as a complete opaque curtain. For More Information on Tech Specs, See 18 oz FR Coated Vinyl Technical Specifications Here.

Red

Yellow

Champion Blue

Royal Blue

Purple

Orange

Forest Green

Gray

Tan

Black

13.5 oz Laminate Vinyl FR - Opaque

13.5 oz per sq/yd Coated Vinyl provides the most economical Vinyl Curtain Material with solid durability. The Vinyl Meets Flame Resistant Standards, CFM, NFPA-701 & ASTM E-84. Generally used on the top & bottom panels but can also be selected as a complete opaque curtain. For More Information on Tech Specs, See 13 oz FR Laminate Vinyl Technical Specifications Here.

Red

Yellow

Blue

Forest Green

White

Gray

Black

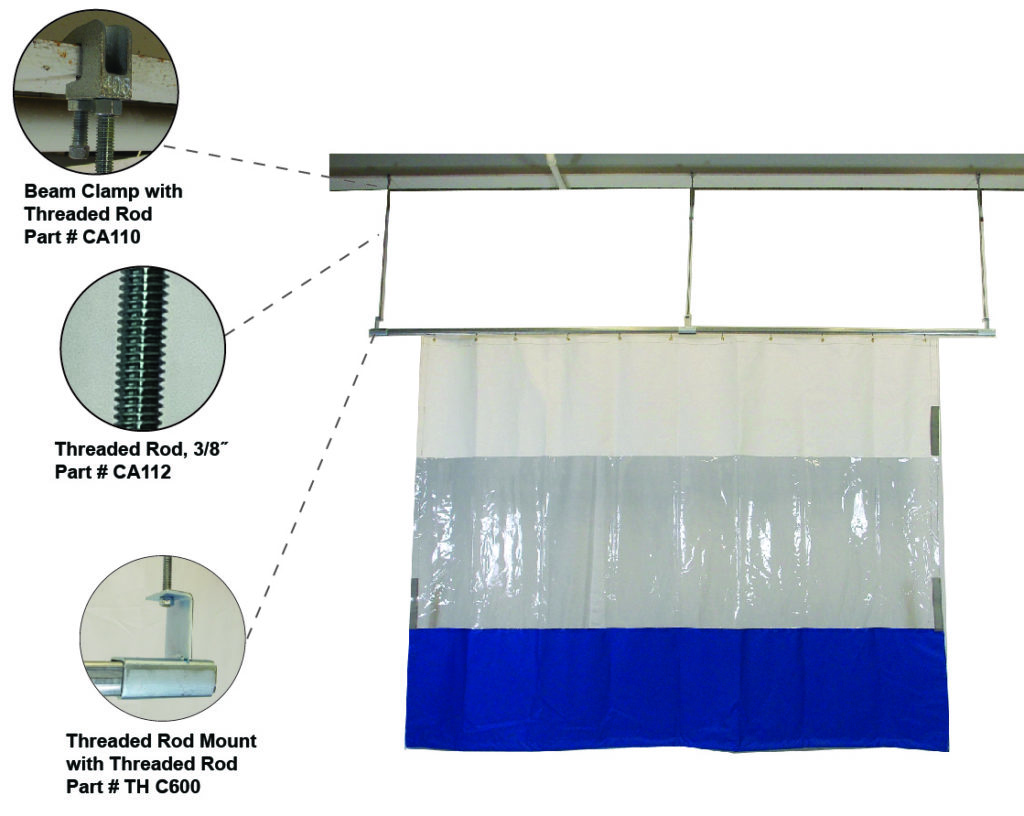

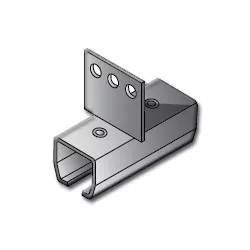

THREADED ROD - SUSPENDED

Track System is mounted in from beams or trusses with a C-Clamp, and using a 3/8″ Threaded Rod to suspend down to the desired height. The Threaded Rod Track Mounts then slide over the threaded rod. Mount Spacing can be from 4′ -8′ with taller heavier systems over 25′ being 6′ or less usually

TH C600

TH C502

TH C503

TH C601

TH C604 Use w/ 500s

TH C900 - Sub for Threaded Rod, Beam to Chain, & Wall

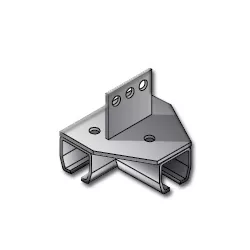

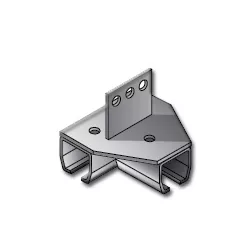

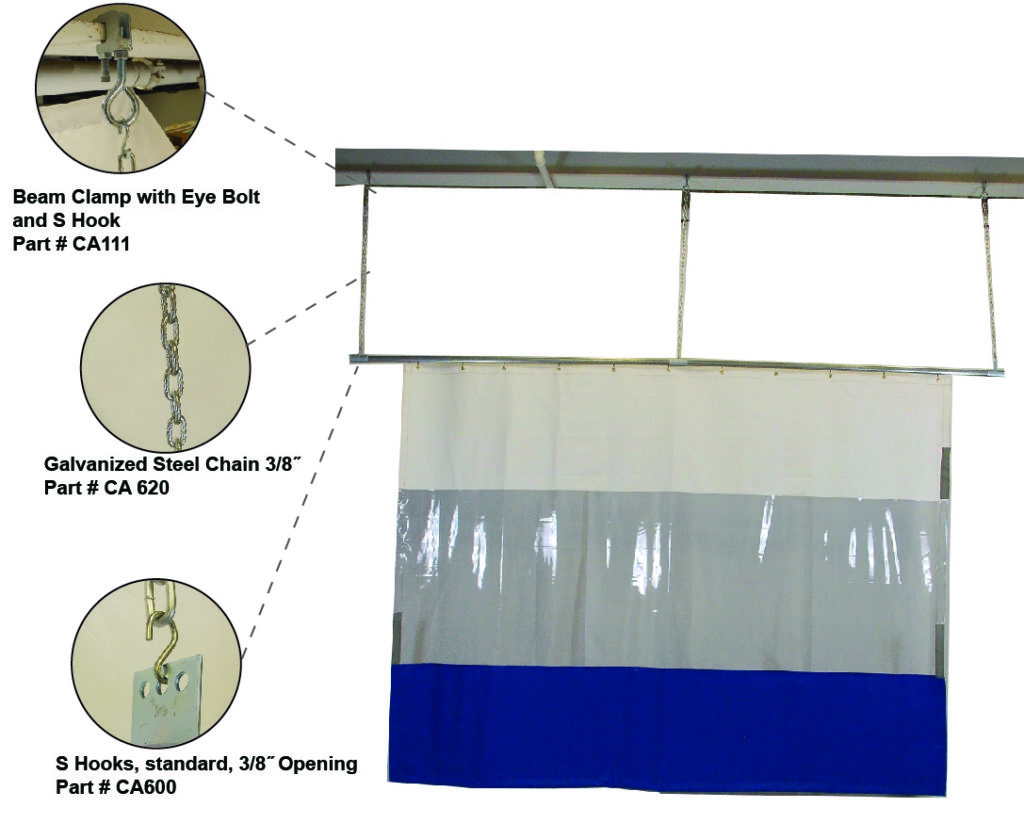

BEAM TO CHAIN - SUSPENDED

Track System is mounted in from beams or trusses with a C-Clamp, and using an S-Hook suspended down with chain to the desired height. The Track Mounts then connect the system with more S-hooks. Aircraft Cable is another option to use instead of chain. Mount Spacing can be from 4′ -8′ with taller heavier systems over 25′ being 6′ or less usually

TH C500

TH C503

TH C503

TH C501

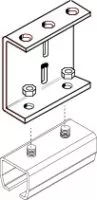

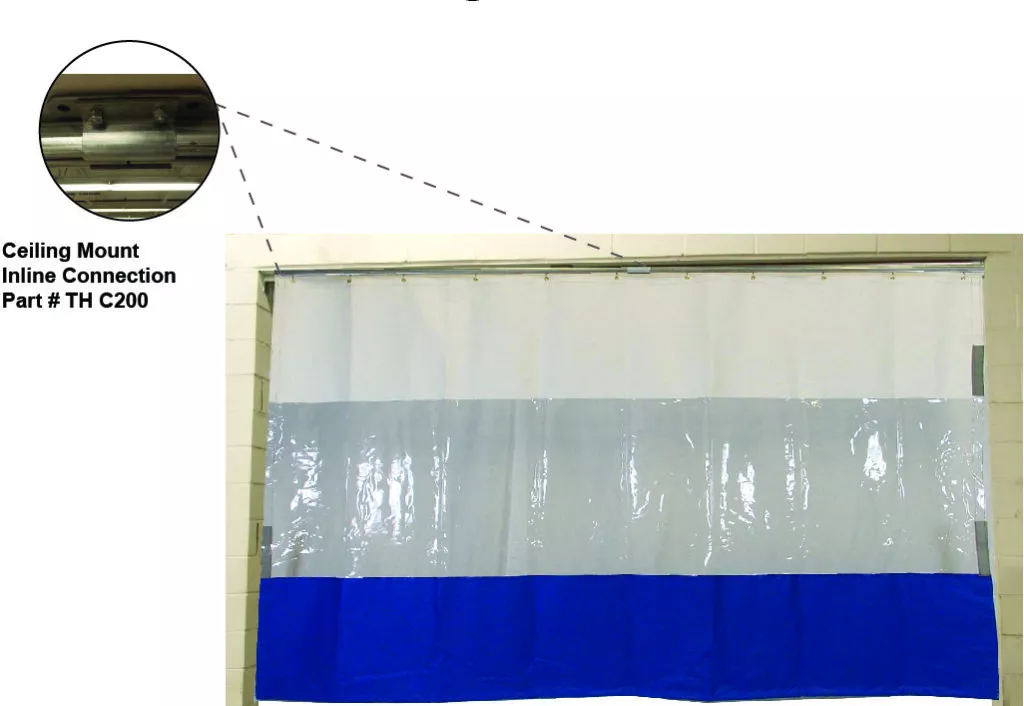

CEILING MOUNT

Ceiling Mount Hardware is attached with lag bolts directly flush to ceiling, floor joists or to steel beams.

TH C200

TH C200

TH C203

TH C201

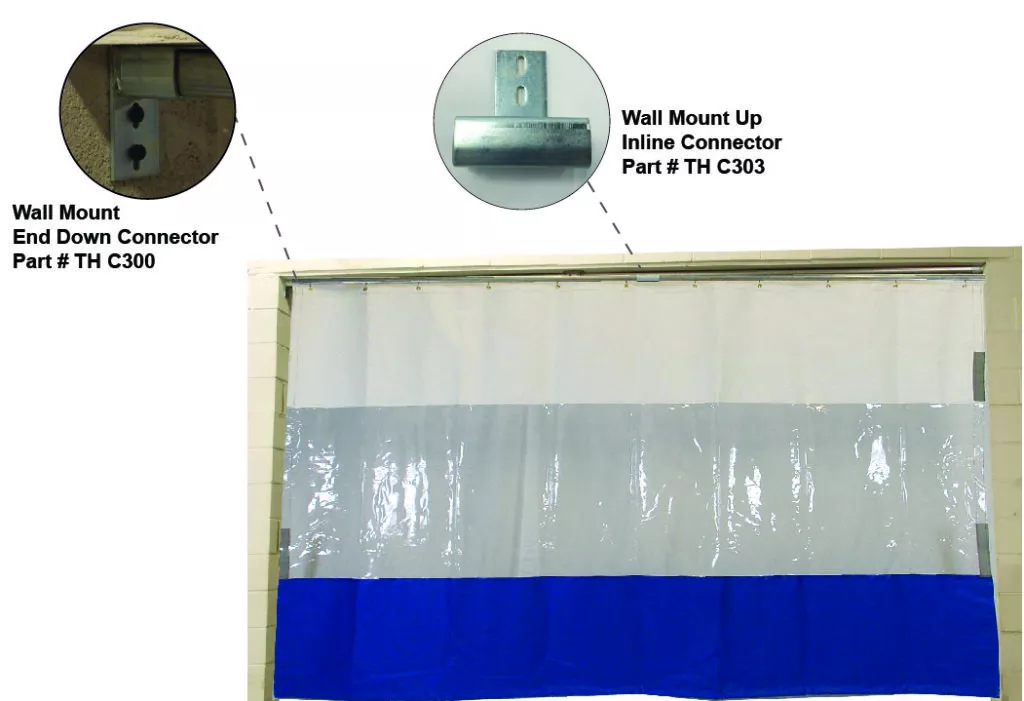

WALL MOUNT

For the Wall Mount installation method, track mounts are attached to walls above openings, or you can use wall end brackets to brace or stabilize the track.

TH C303

TH C302

TH C301

TH C300

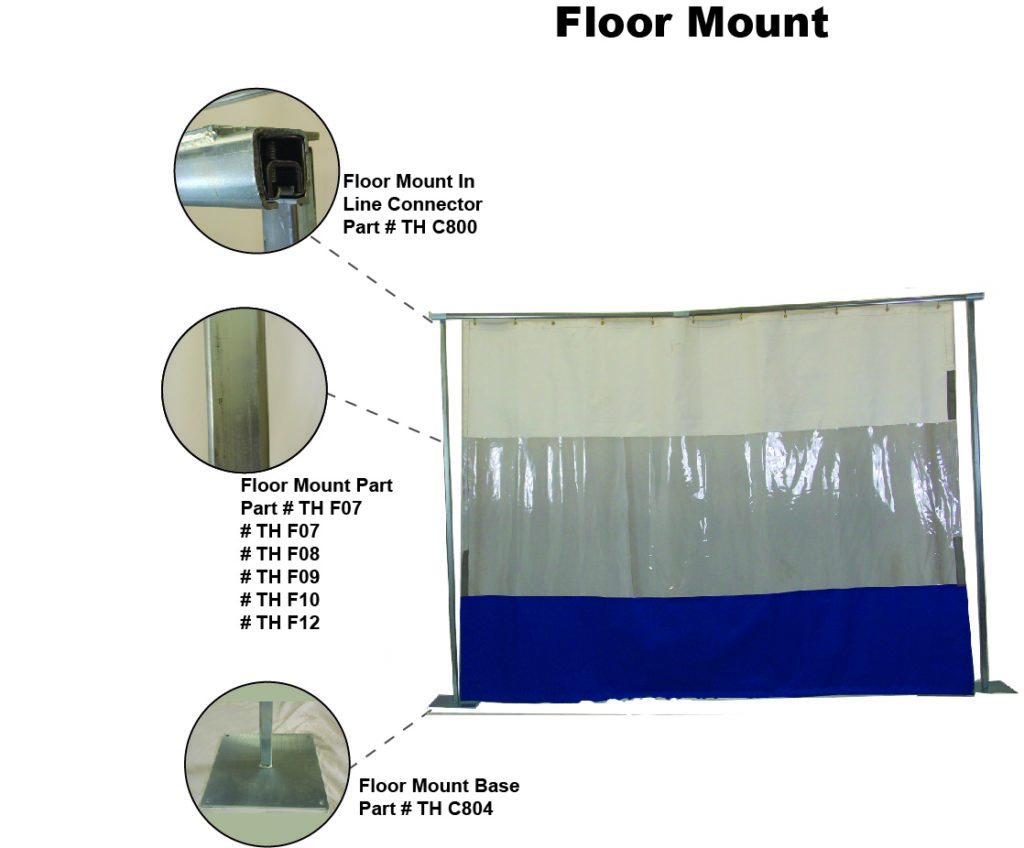

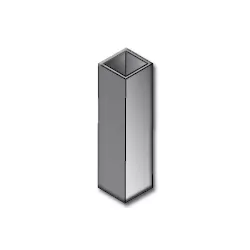

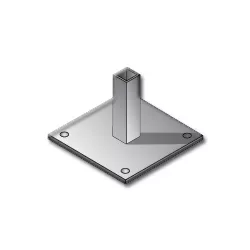

FLOOR MOUNT FREE STANDING

The Floor Mount System which is Free Standing, uses base plates at intervals anywhere from 4′ – 10′ depending on the height of the curtain system. The base plates attach to posts which connect to the floor mount splices.

TH C800

TH C802

TH C803

TH C801

6' - TH F06, 7' - TH F07

8' - TH F08, 9' - TH F09

10' - TH F10, 12' - TH F12

TH C804

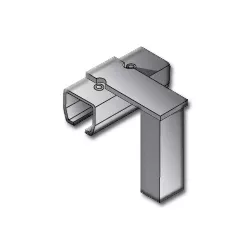

STRAIGHT TRACK, ROLLER HOOKS, & ACCESSORIES

Straight Tracks, Plain Connectors, Universal Mounts, End Stops, as Well as Pulleys to Customize Your Track Curtain System.

TH R101

TH R100

TH C700

4' - TH T04

5' - TH T05

6' - TH T06

7' - TH T07

8' - TH T08

10' - TH T10

12' - TH T12

- Measure the Distance of the Width of the Curtain Laid Out

-

- Steel Guard Adds 3% + 2″ to the Width Of Curtains for Drapage (Unless Custom Spec’d)

- The Track Hardware is the Same Width as Your Order.

2. Measure the Distance from the Floor to the Mounting Point

-

- Paint Booth Curtains with Track come Standard 3″ Shorter to Account for the Track. (For Example a 10′ Height System Measures 9′-9″)

- If you have a Floor Sweep the Size is the 3″ Shorter and the Floor Sweep will Drape and Inch Below the Full Measure Height

- If you are needing to Enclose a Sloped Roof the Track Paint Booth Curtain will be the Height before the Egress. We will need to make Two Triangular Panels. We will need the “Right Side Height”, “Left Side Height, and the Width.

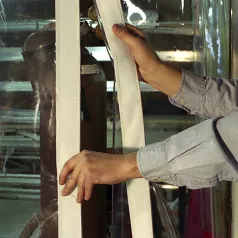

All the Track Parts Connect Modularly

- Layout the Track Pieces & Connectors Along the Floor Right Below Where you Plan to Mount Them.

- Affix One of the End Stops Along the End of the Track (Unless Track is In-between Walls)

- Connect the Track on the Back Side By Sliding the In-Line Connectors Over the Track and Match Up the Holes, Use an All Wrench with Set Screws to Affix

- . Take First Piece of Track and Second Piece of Track and Slide the Left Side of the Next In-Line Connector and One Peice and Right Side of the In-Line Connector.

- Continue this in Perpetuity Untill the Track System is to End.

For More Detailed Information Take a look at our Track Installation Instructions

Typically Track Spacing is Anywhere from 5′-8′ Apart.

Unless the System is very heavy and tall Spacing below 5′ will not be necessary. Most systems up to 8′ will have a “droop of less than 1/8”. This is called the Deflection. Contact one of our Reps if you are Needing Help Determining the Deflection.