American Made, Iron Clad Protected - Discover the Industries Best Warranty.

Acoustic Enclosures | Industrial Sound Isolation Enclosures

Acoustic Sound Enclosures for Industrial Manufacturers

Custom-Built Acoustic Enclosures

Steel Guard offers custom-built acoustic enclosures which create a soundproofing room within a room, designed to provide effective sound proofing solutions for industrial applications. Our sound enclosures are made using a combination of or custom composite materials featuring Mass Loaded Vinyl and Fiberglass. These acoustic blanket panels absorb sound within a contained area, keeping noise energy away from other operations in your manufacturing facility. This not only reduces noise levels but also effectively minimizes stress and fatigue among workers.

Our Sound Shield Acoustic Enclosures are also available in an Outdoor Grade Coated Vinyl Exterior, making them durable enough to withstand extreme weather conditions and temperatures.

Versatile Soundproofing Configurations

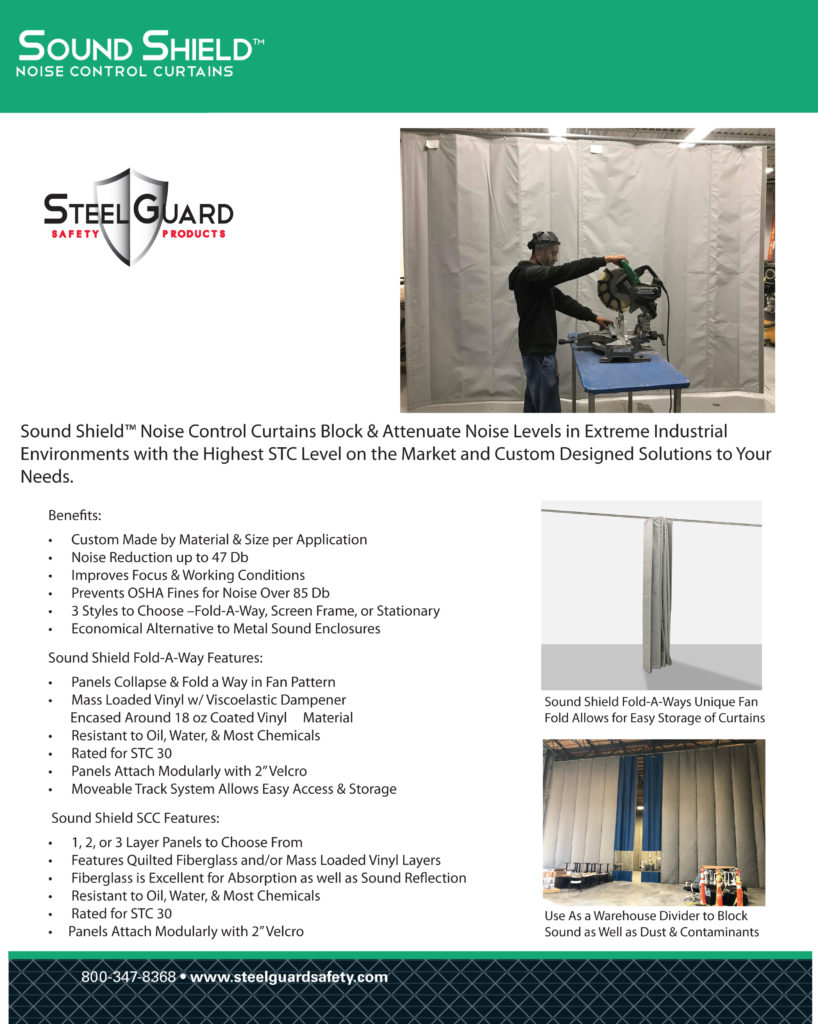

Steel Guard’s acoustic enclosures are custom-configured for soundproofing using our high-quality fiberglass sound absorption and blocking materials. These materials are sewn together and can be attached with grommets, Velcro, or other methods to build the booth. The enclosure is supported by a metal framing system, with an optional sliding curtain track available for easy access.

Applications of Acoustic Enclosures

Our acoustic sound enclosures are ideal for a wide range of industrial applications, including:

- Machine and sound enclosures

- Quiet rooms

- Sound booths

- Control rooms & OC rooms

- Power plant offices

- Generator enclosures

- Outdoor noise barriers

- Printing press enclosures

- Product testing chambers

Additional Information:

Benefits of Using Acoustic Enclosures

Exposure to sound levels above 85 decibels, whether from busy roadways, commercial HVAC equipment, electrical transformers, generators, or noisy warehouses, can pose significant health risks. These include headaches, increased allergy symptoms, insomnia, and other health concerns. Many municipalities and governments have regulations to limit noise levels in communities, making compliance essential for businesses.

What Is an Acoustic Enclosure?

An acoustic enclosure is specifically designed to reduce, minimize, or eliminate sound emanating from a particular source. These structures provide outdoor and indoor soundproofing by dampening offensive noise. Acoustic panels or enclosures are essential for reducing noise pollution and helping businesses comply with local and national noise ordinances.

How Do Acoustic Enclosures Work?

The most common type of outdoor acoustic panels includes a series of noise-canceling or reducing panels, helping commercial and industrial companies maintain compliance with noise regulations. These panels create quieter environments, allowing individuals to work safely away from equipment noise. For indoor applications, acoustic rooms offer quiet spaces for meetings or business operations without interference from traffic noise, HVAC systems, or utility equipment.

Material Options for Industrial Sound Enclosures

SEE MATERIALS TAB FOR MORE DETAILS

SCC-10 – 1″ Fiberglass Batting with Vinyl Quilted Front Plus 1 lb/sq ft Mass Loaded Vinyl Plus 1″ Fiberglass Back with Quilted Vinyl – STC 29 – See More Details

SCC-11 – 1″ Fiberglass Batting with Vinyl Quilted Front Plus 2 lb/sq ft Mass Loaded Vinyl Plus 1″ Fiberglass Back with Quilted Vinyl – STC 33 – See More Details

SCC-12 – 1″ Fiberglass Batting with Vinyl Quilted Front Plus 1 lb/sq ft Mass Loaded Vinyl Back – STC 27 – See More Details

SCC-13 – 2″ Fiberglass Batting with Vinyl Quilted Front Plus 1 lb/sq ft Mass Loaded Vinyl Back – STC 32 – See More Details

Cleaning Acoustic Sound Blanket Materials

Industrial Sound Blanket Material can be wiped down with a rag, or cleaned with a broom to remove dirt and debris from the surface. Any Non Exposed Surface can be cleaned with typical house hold or industrial solvent and detergents.

Sound Shield Enclosures

Standard & Optional Features

SCC Materials

Vinyl Quilted Fiberglass Materials combined with Mass Loaded Vinyl. Several Options. See Details in Materials Tab or Spec Sheets below.

SCC-10 Page

SCC-11 Page

SCC-12 Page

SCC-13 Page

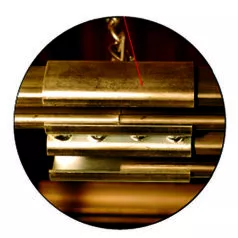

#4 Brass Grommets

#4 Heavy-Duty Brass Toothed Grommets are spaced every 12″ on center of the curtains to hang securely on the roller hooks.

Nylon & Steel Roller Hooks

Used to Hang the Side Curtains in a Stationary Cell or by Using Dual Track Hardware to Slide them Behind Each Other. Larger Systems over 10′ Tall Usually need Steel Roller Hooks.

Part# TH R102 – Steel Roller Hooks

Dual or Single Track Mounting Hardware

Single Track or Dual Track for Sliding Curtains Behind Each Other. 5 Different Mounting Options Available. Including a Universal Mount to use in place for Beam to Chain, Threaded Rod, and Wall Mount. (See Mounting & Hardware Tab)

Sound Shield Roof Panels

Custom Designed Truss Grids with SCC Materials Laid on Top Can be Manufactured to Cover the Roof for Even More Sound Attenuation.

SCC-10 and SCC-11

STC 29

STC 33

SCC-10 SCC-11

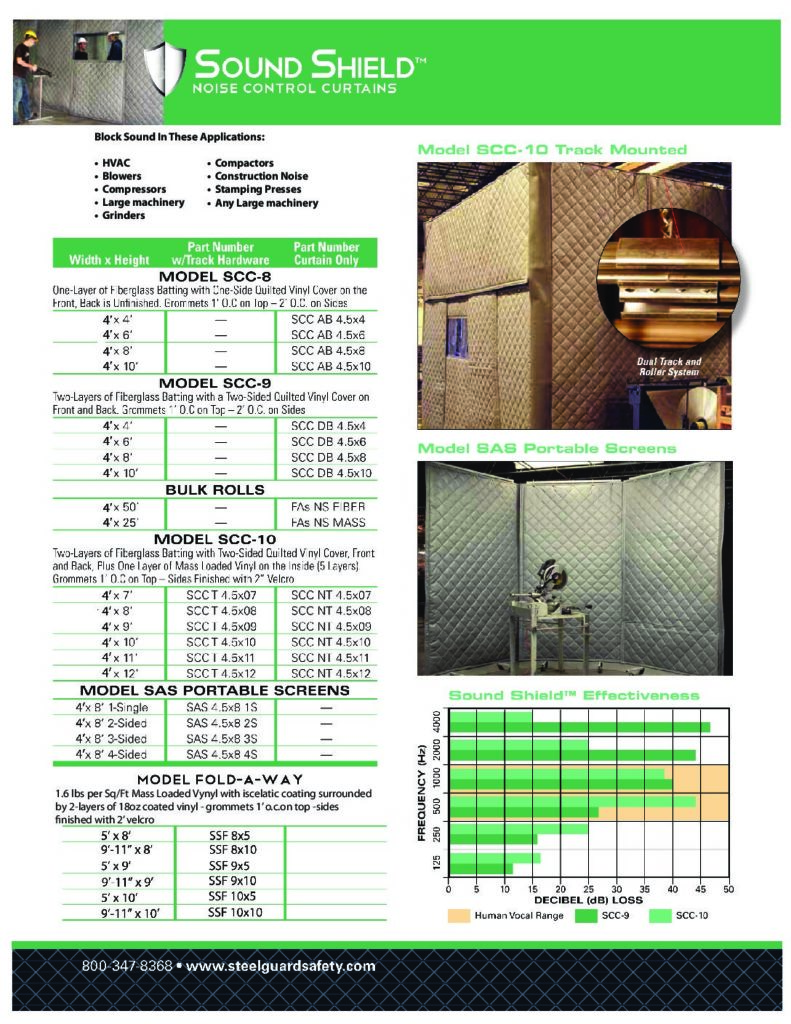

SOUND ABSORPTION (HZ) PER ASTM C423

| Model Number | 125 | 250 | 500 | 1000 | 2000 | 4000 | NRC |

|---|---|---|---|---|---|---|---|

| SCC-10 & SCC-11 | .18 | .62 | .89 | .84 | .60 | .45 | .75 |

SOUND TRANSMISSION LOSS (HZ) PER ASTM E90 & E413

| Model Number | Barrier | 125 | 250 | 500 | 1000 | 2000 | 4000 | STC |

|---|---|---|---|---|---|---|---|---|

| SCC-10 | 1 lb. | 12 | 16 | 27 | 40 | 44 | 43 | 29 |

| SSC-11 | 2 lb. | 19 | 22 | 28 | 40 | 56 | 61 | 33 |

SCC-12 and SCC-13

STC 27

STC 32

SCC-12 SCC-13

SOUND ABSORPTION (HZ) PER ASTM C423

| Model Number | Thickness | 125 | 250 | 500 | 1000 | 2000 | 4000 | NRC |

|---|---|---|---|---|---|---|---|---|

| SCC-12 | 1″ | 0.12 | 0.47 | 0.85 | 0.84 | 0.64 | 0.62 | 0.70 |

| SCC-13 | 2″ | 0.07 | 0.27 | 0.96 | 1.13 | 1.08 | .99 | .85 |

SOUND BLOCKING PERFORMANCE (HZ)

| Model Number | Thickness | 125 | 250 | 500 | 1000 | 2000 | 4000 | STC |

|---|---|---|---|---|---|---|---|---|

| SCC-12 | 1″ | 11 | 16 | 24 | 30 | 35 | 35 | 27 |

| SSC-13 | 2″ | 13 | 20 | 29 | 40 | 50 | 55 | 32 |