American Made, Iron Clad Protected - Discover the Industries Best Warranty.

Blog

How to Install Warehouse Curtains & Industrial Curtain Walls & Choose The Right Set Up

Warehouse curtains are a welcome addition to facilities for a multitude of reasons. They pose as barriers that you can move in section of your warehouse to shield dust, chemicals, heat, cold, and other airy irregularities so that the majority of your staff and inventory remains unaffected. When warehouses regularly use these curtains, they enjoy many benefits which include healthier working conditions, less chance of an accident, and better insulation.

Warehouse curtains are a welcome addition to facilities for a multitude of reasons. They pose as barriers that you can move in section of your warehouse to shield dust, chemicals, heat, cold, and other airy irregularities so that the majority of your staff and inventory remains unaffected. When warehouses regularly use these curtains, they enjoy many benefits which include healthier working conditions, less chance of an accident, and better insulation.

These curtains are exactly what one would expect. They hang from a rail near the ceiling and drape down to the floor, creating a section within the warehouse to keep wanted air in or unwanted air out of certain places inside the facility. These are heavy duty industrial curtains, so they will not move or sway freely. They are made of a type of vinyl which is heavy and padded, so they can take a beating and still perform well for a number of years. If people or vehicle want to move past hung curtains, they can easily do so without moving the curtain on their track. They’ll hang back in place and closed like before so they can continue to insulate and protect.

How To Install Warehouse Curtains

Warehouse curtains are considered a very useful amenity that require a decent amount of work and modification done, so that they can work in your space as intended.

Choose A Type Of Mount

There are a number of types of warehouse curtains you can pick from in terms of how they can be hung. All types of curtains are hung on a track or rail that is mounted along a wall or around a certain space. Curtains are usually hung from the track from a series of hooks, just like traditional shower curtains.

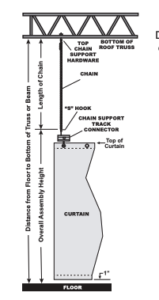

Chain mounts also referred to as Beam to Chain Mounts, involve the tracks being hung from S-Hooks on the Mount-Chain-to Another S-Hook or a Beam Clamp. This mount can be suspended to connect to the most different type of ceilings in a facility. The Chain also can be slightly angled so mounts don’t have to be perfectly in-line vertically like a threaded rod mount has to.

Threaded Rod Mounts use a 3/8″ Threaded Rod is inserted through this mount with a nut to tighten and adjust at the track mount. The upper or top end of the threaded rod is put through a Beam Flange Mount than can grip to a girder or I-beam. This is the sturdiest mount and sometimes required in areas where Earth Quakes are prone.

A beam mount is a simple, versatile mount type. These beam mounts can be clamped onto a lip of a horizontal beam or truss where the track gains support and stability. These are one of the easiest types of mounts to deal with.

Wall mounts involve mounting hardware placed along the wall, so that a curtain can hang over a doorway, port, or other opening inside your industrial space. These are popular on the edges of work areas, in-between rooms or commonly on plenums in Paint Booth and Finishing Stations.

Ceiling mounts come with special hardware that are screwed into your ceiling. You will typically have hardware to accommodate for each straight path. The mounts can also be tack welded directly to I-Beams Girders or any metal ceiling.

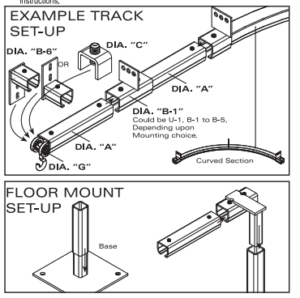

Floor mounts are also available for industrial warehouse curtains. They must be bolted into your warehouse floor per OSHA requirements, so that the curtains don’t fall over causing accidents. Floor Mounts are ideal for simple installation when complex piping and obstructions are present in a warehouses ceiling.

Diagrams of Different Types of Sample Curtain Track Mounting

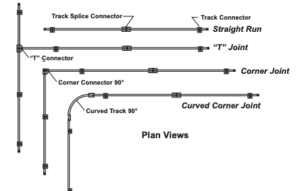

Map Out the Track System

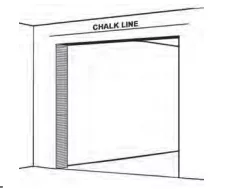

The Track Mounting will determine where your industrial curtains can move and be displayed. Tracks generally have a beginning and an end where curtain can be hung, so curtains should not be able to move beyond these boundaries unless a custom run is added in another direction. Generally, the Curtains will fold to about 10% of the full width. In specialty circumstances an off shoot track length can be added in a different direction to allow a fully open access point. If you are looking to install multiple sets of curtains in your warehouse, you will need to plan ahead an up determine where tracks should be mounted that cover all the different areas. If you have a floor plan for your space, you can draw chalk lines with circles of where would you like to plot the industrial warehouse curtains. If two lines or circles touch or criss-cross, then you can make changes to your plans to so that there won’t be any complications when you go to install your curtains.

The Track Mounting will determine where your industrial curtains can move and be displayed. Tracks generally have a beginning and an end where curtain can be hung, so curtains should not be able to move beyond these boundaries unless a custom run is added in another direction. Generally, the Curtains will fold to about 10% of the full width. In specialty circumstances an off shoot track length can be added in a different direction to allow a fully open access point. If you are looking to install multiple sets of curtains in your warehouse, you will need to plan ahead an up determine where tracks should be mounted that cover all the different areas. If you have a floor plan for your space, you can draw chalk lines with circles of where would you like to plot the industrial warehouse curtains. If two lines or circles touch or criss-cross, then you can make changes to your plans to so that there won’t be any complications when you go to install your curtains.

Tracks are mounted on walls, beams, or ceilings with bolts or screws. If you are looking to hang curtains to protect multiple areas along the same wall, you can make one long track in a straight line so that you can hang multiple sets of curtains on the same track.

If you are installing curtains in an area where there is no wall to mount from, or you prefer to not use a wall mount, you can hang your tracks from the ceiling instead. With a facility that is already full of resources, you probably have possible points on the ceiling where your track can be hung from, such as horizontal beams. If not, a beam to chain suspended mount can be altered to fit in vertical directions that are not completely straight up.

Unless you have a catwalk or upper area of your facility that you can safely access, or track that you can access from ground floor, you may need to use a safe lift or ladder to be able to reach your tracks and insert the bearings into the slots that they need to go in.

A lift is hands down the safest and most effective means to reach your warehouse ceiling from the ground floor, and depending on the size of its platform, it can accommodate more than one person. If you do not have a lift, we strongly consider buying or renting one to install your warehouse curtain tracks. There are many types of lifts to consider, but two that can work for this specific job include scissor lifts or electric boom lifts, both are great for indoor areas where you don’t have much room to work in.

Connect System Together

While each type of curtain mount is fastened in a different way, they all basically involve working a steel roller whee with ball bearing inside should move freely in the track slot. When properly inserted, the roller wheel should be able to move smoothly along the track, with the set of curtains following.

To ensure that the bearings do not fall off ceiling-mounted tracks, there is usually a lock or cap that is fastened on both ends of the track so that all the roller wheels stay put. These Roller wheel wont fall or move out unless you remove the end stops.

Are Warehouse Curtains Right For You?

If you do not yet have any warehouse curtains for your facility, there might be a few scenarios in which they are a good idea to have. If you have recently experienced an unexpected event like a dust explosion, pest infestation, a bunch of tampered products, or a group of sick employees, all these things can be prevented the next time around with warehouse curtains installed in the right places.

Additionally, if you are noticing that you need to use your air conditioner or heater more than you would like to, it may be because of a port or entry point from outside where vehicles come in and get out. With warehouse curtains, you can also keep this port open without letting cold or hot air in. As a result, you won’t need extra power from your heating and cooling units, saving you money with each season.

Conclusion

Warehouse curtains are great assets for any warehouse, facility, factory, or other industrial setting. By setting aside the time and money to purchase and install these curtains, you will solve and prevent multiple problems with your space, leading to fewer expenses and more money saved in the near future. There is no reason not to take advantage of warehouse curtains in your space.

Recent Posts

- 7 Common Mistakes to Avoid When Setting Up Machine Guarding Fences

- Industrial Curtain Walls: 6 Reasons Why Manufacturing Facilities Must Have Them

- Industrial Soundproof Curtains: How to Decide Between Floor-Mounted and Ceiling-Mounted Curtains

- How to Transform a Noisy Open-Plan Office with Acoustic Baffles

- A Guide to Choosing the Best Concrete Blanket for Construction Projects

- Porch Curtains: 8 Amazing Reasons to Install These Curtains in Your Home

- Chemical Splash Curtains and Their Applications in Different Industries

- Outdoor Sound Curtains for Farms and Animals

- Construction Sound Barriers: Why Every Construction Site Should Have These?

- Industrial Blackout Curtains and Their Applications in Different Settings

Categories

- Accordion Fold Curtains

- Acoustic Baffles

- Agri-Shield Curtains

- Auto Body Shop Curtains

- Bio Plastics

- Industrial Divider Curtains

- Industrial Safety Products

- Insulated Curtain Walls

- Machine Guard Safety Fencing

- Mesh Curtain Screens

- Outdoor Curtains

- PVC Strip Curtains

- Soundproof Noise Blocking Curtains

- Spray Paint Booth Curtains

- Tarps

- Thermal Curtains & Covers

- Uncategorized

- Warehouse Dividers

- Welding Blankets

- Welding Curtains

- Welding Screens