American Made, Iron Clad Protected - Discover the Industries Best Warranty.

Insulated Warehouse Curtains | Thermal Curtain Walls

Energy Shield Foldable Insulated Warehouse Curtains – The Ultimate Temperature Control Solution for Warehouses

Insulated Warehouse Curtains with advanced 3M Thinsulate Fold-A-Way thermal technology offer a cost-effective method to divide temperature zones in various applications. Whether you need to separate warehouse cold storage areas such as, freezer-to-freezer, cooler-to-cooler, or freezer-to-ambient storage areas, these curtains provide the perfect solution. Ideal for food storage facilities and other temperature-sensitive work areas, they are easy to move and modify, folding down to 1/3 of their original size to allow access for large machinery or equipment.

The Insulated Warehouse Curtains come with our roller Curtain track hardware, as well as many options including strip doors, valance panels, floor sweeps and more. R-Values range from R-3 to R-9 for Folding Insulated Curtains. For higher R-Values see our range of Stationary Insulated Warehouse Curtains.

Insulated Warehouse Curtains Features:

- Versatile Applications: Perfect for freezer, cooler, ambient storage, and food storage areas.

- Easy Maneuverability: Folds to 1/3 of its size, allowing easy access for large machinery.

- Roller Curtain Track Hardware: Comes with roller track hardware and options like strip doors, valance panels, and floor sweeps.

- High R-Values: Ranges from R-3 to R-9. For even higher insulation, consider our Stationary Insulated Warehouse Curtains for up to R-15.

- Customizable Sizes: Available in various sizes to fit small areas or divide entire warehouses.

- Cost-Effective: Less expensive than fixed walls and quick to install and remove as needed.

- Multiple Hardware Options: Choose from rolling hardware for movable applications or static hardware for fixed installations.

Additional Information:

Why Choose Insulated Warehouse Curtains?

Insulated warehouse curtains are preferred over fixed walls because they are less expensive, quicker to install, and can be easily removed when not needed. These curtains are an excellent temperature control solution, helping to maintain different temperature zones efficiently.

Hardware Options:

Rolling Hardware: Allows the curtain to be rolled from side to side for flexible access.

Static Hardware: Ideal for non-moving applications where a fixed barrier is needed.

Order Your Custom Quote Today

We offer a range of standard sizes, but if you need a custom solution, simply click the Request Quote Button and fill out the form. Our team will provide you with a tailored quote to meet your specific requirements.If there’s an insulated warehouse curtain panel size you need that you can’t find on our website, custom sizes are available to meet individual project needs. We also provide multiple panel insulation options up to R-15 to provide varying levels of protection depending on the application.

Common Applications of Folding Thermal Curtain Walls

• Refrigerated & freezer areas

• Warehouse separation with temperature controlled space

• Loading dock areas

• Containment for storage and work space

• Food & beverage industry including food processing lines

Energy Shield Insulated Curtains - Folding

Energy Shield FT I

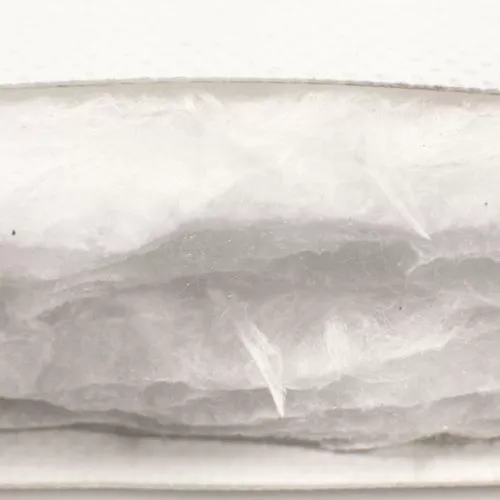

2-Layers of 18 oz Coated Vinyl Sandwiched around 1 Layer of Thinsulate 3M Ultra. Meets ASTM E-84 and NFPA-701 Certifications.

Provides Temperature separation of 17 degrees F (9 degrees C). < See Materials Here >

Energy Shield FT II

2-Layers of 18 oz Coated Vinyl Sandwiched around 2 Layer of Thinsulate 3M Ultra. Meets ASTM E-84 and NFPA-701 Certifications.

Provides up to 24°F (13° C) of temperature separation; R-Value of 6.0. < See Materials Here >